A Premium CDMO with Complex Capabilities

Bora’s capabilities cover a wide range of technologies for clinical and commercial manufacturing of oral solids, semi-solids, and liquids in various forms – tablets, capsules, granules, liquids, semi-solids, and nasal sprays.

Find the perfect technology-drug product match

Successful drug development relies on matching the needs of your drug product with the right technologies and a skilled team with the operational strengths to deliver a high-quality product on time.

At Bora, we have the expertise and capabilities to handle high-potency compounds, solvents, flammables, and various controlled release profile products to cGMP manufacture and packaging a range of drug products.

World-Class Technologies

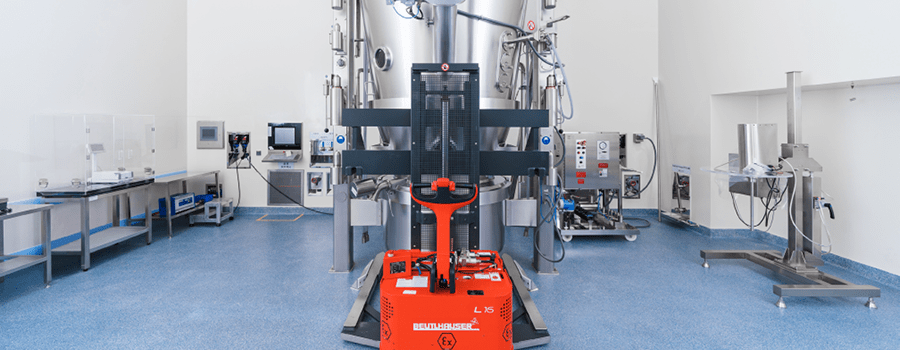

Handling Solvents

Solvents – used to dissolve, disperse, suspend, or extract key materials during drug manufacturing – come with several processing challenges. At our sites in North America and Asia, we have the expertise and capabilities to handle solvents in large scales.

Modified Release

Time-release formulations such as extended/delayed release OSDs allow convenient dosing, improved compliance, and fewer drug fluctuations throughout the day. Bora has extensive experience in specialist drug delivery technologies such as E-S and Wurster coating to manufacture complex OSDs with intermediate release and controlled release (sustained, pulsed, modified, and delayed) profiles.

Extrusion-spheronization

Extrusion-spheronization, a sophisticated pelletization technique, improves safety, efficacy, and dose compliance across a diverse range of therapeutic areas.

Bora’s formulation skills and experience with the mechanisms of E-S formulations combined with high-throughput manufacturing allow us to deliver controlled-release oral solid dose (OSD) medications with better yield and less waste in the process.

Wurster Coating

Extended- or modified-release pharmaceutical formulations typically feature a functional coating to delay the release of the drug in the body.

At Bora, we have mastered Wurster coating using bottom-spray fluid-bed technology to manufacture these drugs.