Cell line development insight boosts active protein productivity more than five times

Q-Sera, an internationally recognized biotech innovator engaged Bora’s team to develop and manufacture an innovative active protein, RAPClot™ (ecarin), a key component of its proprietary coating to improve the function of a serum-based blood testing device. Blood collection tubes are coated with RAPClot™ formulation, resulting in tubes which rapidly produce high quality serum form samples, including those containing anti-coagulants (which current serum tubes cannot do). RAPClot™ tubes have been designed to replace currently used biochemistry tubes with benefits that may translate into cost efficiencies and reductions for healthcare systems and improved outcomes for patients worldwide.

Found in some snake venoms, a recombinant version of ecarin is being developed by Q-Sera and Bora from mammalian cell lines. Adding to the project’s complexity, the protein is expressed initially as a larger protein which after cleavage (activation step) becomes the active protein.

Overcoming low-yield issues critical to commercial success

Internally developed from a commercial cell line production clone, the enzyme yield was too low to make it a commercially viable alternative to currently available biochemistry tubes. The novel enzyme-coated blood collection tube has to compete on unit price and production cost with devices currently coated with silicon and other substances.

However, the distinct advantages of the enzyme-based coating were too compelling to ignore and prompted the innovator to seek the support of an external contract development and manufacturing organization (CDMO) to increase the production yield of high purity RAPClot™. Their search for a strategic partner to develop the potential and productivity profile of RAPClot™ led to a collaboration with Bora’s cell line team and its offer of expert early-stage cell line development (CLD) support.

Accessible cell line services open door to novel product’s potential

To open a new door of development and commercial potential, Bora’s cell line services provided a proof-of-concept study using its proprietary CHO cell lines that allowed the customer to evaluate Bora’s experience with enzyme-based organic chemistries, processing technologies, and manufacturing capabilities.

The proof-of-concept demonstrated that Bora’s very early CLD platform data (cell pools performance/data) was greater than the productivity profile of the customer’s original clone. Our team then used that expertise to select the highest-performing clone In light of Bora’s previous and successful experience on enzyme projects, the path to success for this active enzyme technology had already been well established.

Given the robust data from its CLD platform and past experience, Bora Biologics technical team knew it could expect about a 5X yield improvement based on that cell pool’s productivity profile. To Q-Sera, it quickly became evident that Bora was an obvious choice to complete both the cell line and cell culture development work.

A tailor-made solution emerges to meet an aggressive drug strategy

To express the enzyme efficiently and achieve productivity goals, Bora Biologics’ proprietary CLD platform based on CHO cells provided the foundation to optimize the production process to increase the yield of this particular molecule. Leveraging platform methods, Bora Biologic’s technical team tailored CLD and cell culture process to attain a more stable and efficient process and enhance the yield and quality of this molecule.

The productivity improvement was quite evident at 5X improvement: To improve downstream processes and efficiency, the Bora Biologics team then:

- Developed a new and more efficient activation step which further improved yield by 10-15% and cut costs

- Reduced multiple UF/DF steps in between chromatography steps to optimize the process

- Streamlined the client’s three-column process to a two-column process, improving quantitative purity in the process

The value-add for this customer came from Bora Biologic’s experience in dealing with complex molecules as well as expertise in identifying and selecting the highest-performing clones.

Michael Grant, CEO of Q-Sera, says, “Commencing with the Partnering program for promising technologies and initial collaboration, Q-Sera subsequently engaged Bora Biologics to develop its RAPClot™ protein to the current completion of the downstream step. We have been impressed with Bora’s initiative, innovation and commitment to the project.”

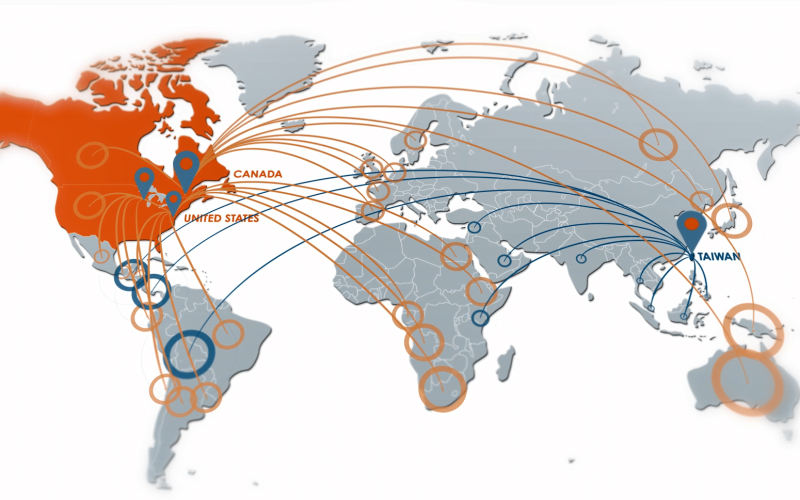

Collaborations with better outcomes: Bora Biologics

Biotech innovation, as well as viable therapeutic molecules, are coming from all corners of the planet. Uncovering a molecule’s true therapeutic potential and patient value is central to contemporary drug strategies, not to mention the strategic alliances necessary to get drugs to patients faster. Based on the function/format of the molecule and decades-long experience with similar functions and formats of these kinds of drug substances, Bora Biologic’s technical teams can quickly tailor the cell line/cell culture process to accelerate product potential, meet market demands and timelines and reach patients faster.